AdvanSource

We offer biomaterial products that support short and long-term implant performance and smoother device insertion and removal.

We offer biomaterial products that support short and long-term implant performance and smoother device insertion and removal.

ChronoFlex™ S is the softest, non-plasticized TPU available for implantable medical devices, delivering short and long-term in-body performance without the complexity of additives or secondary materials. At 60A Shore hardness, it delivers strength, durability, and processability of a polycarbonate-based TPU, without adhesives, plasticizers, or tie layers.

Engineered for both short- and long-term implantation, ChronoFlex S combines exceptional softness with high tensile strength, oxidative stability, and in-body conformability. The result is a material that helps to reduce mechanical mismatch with tissue while enabling thinner walls, simplified manufacturing, and more advanced device designs.

Mitsubishi Chemical Group’s AdvanSource Biomaterials products are an ISO-certified materials technology company specializing in medical-grade materials for long- and short-term implants and disposable products and applications.

These medical-grade materials have the versatility to be used across a broad array of applicational areas.

Designed for medical devices requiring long-lasting agility and lubricious coatings for slip-to-aid device insertion and removal.

ISO Certificate

Product Overview

Mitsubishi Chemical Group has a long history of reliable performance in long- and short-term Hydrophilic devices. These medical-grade materials have the versatility to be used across a broad array of applicational areas ranging from oncology and orthopedics to cardiovascular disease management.

Our polycarbonate-based materials withstand environmental stress cracking (ESC) commonly associated with in-vivo implantation. They display a low modulus of elasticity, excellent solvent resistance, and limited softening in-vivo while possessing inherent mechanical strength and the ability to minimize surface degradation, such as stress-induced micro-fissures.

Our polyether-based polymers have less in-vivo softening than other industry-recognized ether-based materials and a long history of reliable performance in short-term implantable devices for a broad range of applicational areas. As a result, our polyurethane elastomeric alloys are ideal for replacing rubber, silicone, or latex in many applications.

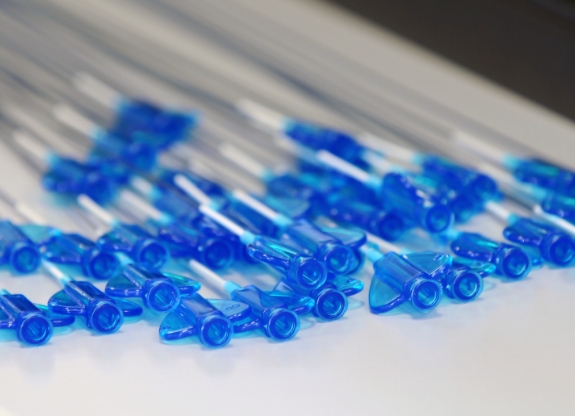

Our hydrophilic materials are designed for use in a wide array of devices, including catheters, guidewires, introducers, and valves. These materials can be tailored to various water absorption, and expansion levels depending upon end-product requirements and are available in extrudable and injection moldable grades.

Mitsubishi Chemical Group has a long history of reliable performance in long- and short-term Hydrophilic devices. These medical-grade materials have the versatility to be used across a broad array of applicational areas ranging from oncology and orthopedics to cardiovascular disease management.

Our HydroMed polyurethanes are designed for medical devices requiring long-lasting agility and lubricious coatings for slip-to-aid device insertion and removal.

Exhibiting superior characteristics of hydrophilicity, HydroMed has equilibrium water contents approaching 90% and can be processed using conventional solvent coating methods that adhere to a wide array of metallic and polymeric substrates.

MCG provides each of the HydroMed grades in solution form. In addition, custom formulations can be developed based on individual device requirements to provide targeted lubricity, adhesion, and thickness levels.